Technological complex for utilization of municipal wastes

more details

Municipal Solid Wastes

- about 1 billion m3 accumulated on landfills;

- each year this increased by 12 million tons;

- total area of landfills more than 7 thousand hectares;

- number of landfills in Ukraine up to 6000;

- most wastes can be used as a fuel resource.

Sewage Sludge

- untreated sludge disrupt environmental safety, human health and living conditions;

- amount of accumulated sludge exceeds 5 million tonnes;

- all major forms of bacteria can be found in sewage sludge.

Used Car/Truck Tires

- about 2 million tons of used car tires are produced annually in Europe;

- only 23 percent of used tires are disposed burning of 1 ton of used tires — 270 kg of soot and 450 kg of toxic gases are emitted;

- tires discarded at landfills are decomposing for at least 100 years.

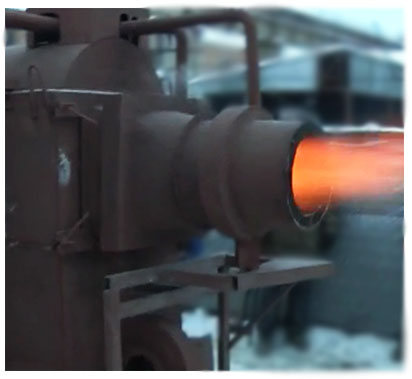

Innovative Waste Recycling Technology

An innovative no-burn and low emissions technology of continuous high-temperature pyrolysis is proposed to solve the problem of energy efficient and environmentally friendly disposal of municipal solid wastes, sewage sludge from the municipal wastewater treatment plants and other types of waste.

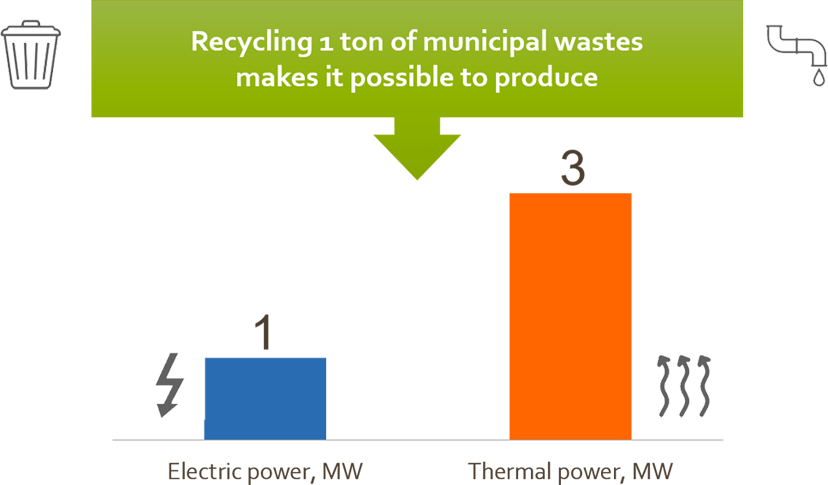

The technology ensures the production of highly liquid products: electricity and thermal power with the use of any kind of carbon-containing waste as a fuel, and receiving additional income from providing wastes disposal services.

Installation for the Wastes Processing

- The principle of technology operation is based on the high-temperature thermochemical conversion of carbon-containing wastes in an oxygen-deficient environment without direct burning of waste, which results in the the production of multicomponent hydrocarbon syngas with high calorific value.

- This gas is used as a fuel for the production of thermal and electric energy. It is much cheaper compared to conventional energy sources and allows for the high economic and environmental efficiency of the installation.

Results of Municipal Wastes Recycling

Installation for the Wastes Processing

|

|||||

|

|||||

| covering the needs of own consumers (thermal and electric energy, cooling power) | deliveries to local consumers (heat and electricity) | deliveries to the network through the regulated energy market (electricity) | |||

|

|||||

| plastic wastes | blades of wind turbines with expired service terms | sorted MSW components | sewage sludge from the municipal wastewater treatment plants | used car/truck rubber tires | chicken manure, pig/cow manure, poultry, slaughterhouse wastes, other agro-waste |

Advantages of the Technology

- Provides the possibility of using biological raw materials with a humidity of up to 70% and ash content up to 90% with the replacement of fuel resources;

- There is no direct incineration of waste, which ensures high environmental friendliness of the equipment;

- Works on virtually all types of alternative fuels;

- It is easy to match with existing models of steam and hot water boilers, as well as drying installations in industry;

- There is no need to make changes in the design of the boiler;

- Modular design enables adaptation to a different ranges of installed capacity and wastes amount to be disposed;

- Provides reduction of CO2 and NOx emissions to the atmosphere;

- Easy to operate and repair.

Possible Types of Wastes

- sewage sludge from municipal water treatment plants;

- sorted municipal solid waste;

- various plastics wastes (bottles, packaging, etc.);

- rubber wastes (used car tires, etc.);

- waste automobile oils, waste products, etc.;

- waste of animal origin (bird droppings, manure, etc.);

- agricultural wastes, other biomass (grass, leaves and branches of trees);

- wastes from woodworking industry.

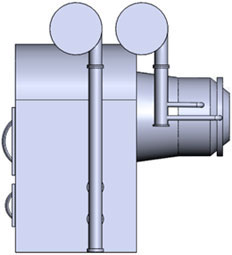

Technical Characteristics of the Heat Generator

| Productivity of the heat generator on raw materials (for sewage sludge with humidity 70%), kg/h | 950 |

| Output heat power of the heat generator, kW/h | 600 |

| Air consumption, m3/h, up to | 3260 |

| Energy consumption, kW/h, max | 7 |

| Requirements for raw materials: | |

| — humidity of the incoming sludge sediment, % | 70 |

| — humidity (after drying in flue gases), % up to | 25 |

| — ash content, %, up to | 90 |

| — particle size (depending on the type of raw material), mm | 0,5-5 |

|

Resulting products: — thermal energy in the form of a torch with temperature — inert ash or pyrocarbon (as required) |

1000-2300 |

| Dimensions, mm: | |

| — length | 4450 |

| — width | 2100 |

| — height | 3050 |

| Volume of loading hopper, m3 | 2,48 |

| Occupied area, m2 | 9,14 |

| Weight of installation, kg | 3000 |

Environmental Safety of Technology

- technology works on the principle of high-temperature destruction of carbon-containing substances, with the subsequent burning of the gaseous products obtained in the combustion channel;

- structural separation of the the raw materials pyrolysis zone and the combustion channel eliminates the flow of carbon and dust particles into the flow of exhaust gases, preventing the possibility of re-synthesis of dioxins;

- ecological safety of the technology is confirmed by the conclusions of scientific institutions and institutions of the Ministry of Health of Ukraine (safety of emissions in flue gases and in ash).

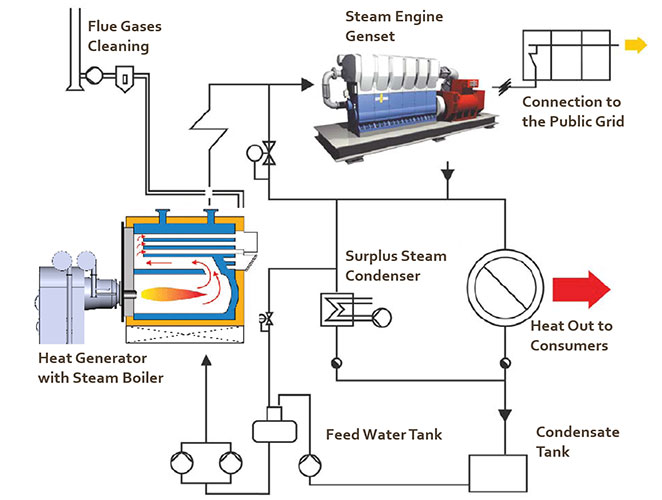

Generation of Heat and Power from the Wastes

The possible technological solution proposed for use for the purpose of energy production from the sewage sludge disposal process is combination of pyrolysis technologies for the destruction of carbon-containing waste with cost-effective and highly efficient power plants based on steam engines of different types

Possible Composition of the Technological Complex

- Wastes (sewage sludge) preparation site:

- receiving hopper for the dehydrated sludge;

- auger press-extruder for sediment briquetting;

- tunnel belt dryer;

- hopper for sludge briquettes storing;

- shredder — hummer-crusher;

- operative fuel supply hopper;

- Pyrolysis heat generator;

- Standard steam boiler;

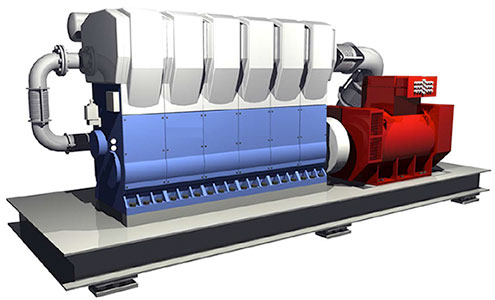

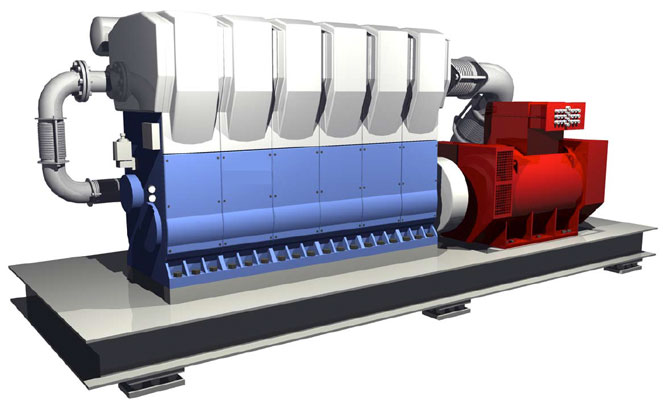

- Steam power generator set (Nel, from 250 kW);

- Flue gas cleaning and exhaust system;

- Process control automation system.

Schematic Diagram

Steam Engines

- suitable for the projects with small to medium installed capacities (100 — 1200 kW)

- extremely large service life of steam engines — 165,000 hours higher efficiency of steam engines compared to turbines same power level

- operate in a wide range of steam pressure — from 0.5 to 4.0 MPa (5 — 40 atm.)

- simple design solutions, compared to steam turbines

- easy to operate and repair

- serial production of steam engines in EU countries

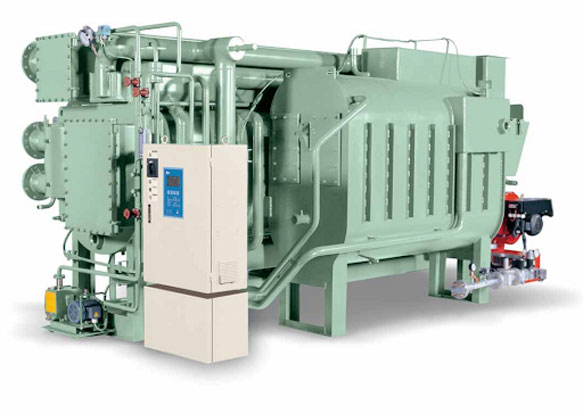

Absorbent Chilling

- considerably lower costs of electric energy, due to the fact that cooling is achieved at the expense of not electric, but heat energy

- ecological safety by refusing to use refrigerants on the basis of fluorocarbons

- reduced noise at work of equipment, absence of vibrations

- lack of high pressure in the system

- the absence of massive moving parts

- high reliability of installations

- low cost of service

Project Management Process

In the frame of the project management process to create a technological complex for the energy-efficient utilization of municipal waste, the company’s specialists will provide the following functions:

- design of pyrolysis heat generators and power stations of various capacities, able to work on different types of raw materials;

- preparation and reception of permissive documentation for construction of facilities in accordance with the requirements of legislation and environmental requirements;

- planning of works and development of design documentation;

- construction management, technical supervision;

- «turnkey» construction, put into operation.

The One Solution to Many Problems

Waste management issues have become one of the most important environmental issues since artificial materials have become widespread, remaining buried in waste dumps for tens or hundreds of years, poisoning soil, water and air.

The proposed technology of high-temperature continuous pyrolysis for waste utilization promotes not only the solving of environmental problems, but also solving the problem of energy resources shortages.

The offered technological complex can be compared with a small thermal power plant, where instead of expensive energy resources municipal waste will be used.

The equipment allows to produce thermal and electric power, with the reuse of biological and industrial materials, while eliminating the need for landfills and garbage dumps.

Contacts

-

Phone number:

+38 (063) 734-15-07 -

E-mail:

ihor.vishnyakov@ekokemika.com.ua -

Address:

47 Elektrotechnicheskaya Str.

03150 Kiev, Ukraine